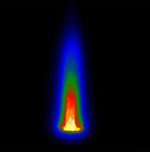

| HOME | LOCATIONS | FLAMMABILITY | HEAT RELEASE | SMOKE DENSITY | TOXICITY | FLAME PROPAGATION | CIRCUIT BOARD |

| FAQs | CONTACT | . | . | DATA FORMS | SHIPPING | SPECIMENS | LINKS |

|

24662 Rhea Drive (949) 859-3569

|

SPECIMEN REQUIRMENTS |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

Submitted specimens must conform to very rigid specifications. Most of the tests are designed to utilize a specific area for the apparatuses to determine the results. All specimens must be bundled in sets of four (4) and labeled. The tests commonly require only three specimens to complete a test, however some specimens have certain explosive characteristics. These characteristics might invalidate one sample and another must be run in its place. One set of four (4) specimens is required for each surface " face" that needs testing. One additional set of four (4) specimens is required if the "face" is known to have isotropic flame properties (such as fabrics, woven materials). One set of four (4) is required for flaming and one set of four (4) is required for non-flaming (smoke density or, toxicity) if required. Important note:Each set of specimens must be accompanied by their own FAA Form 8130.3. Also, the specific test required must be called out in an approved test plan. If these two items are not met we can still test the specimens and issue preliminary results. However, the results will not be certifiable to the FAA. The following is for one sample size, four of each should be provided. (for bunsen burner, heat release, smoke density, 4 for each mode required - Flaming/Non-Flaming)

** Airbus states that the entire printed circuit board must be tested, not just a representative sample. If the printed circuit board is larger that the required size, than it is best to cut the board into equal size pieces that are 4.9" X 6.7" or smaller. Each piece of the entire board must be tested and then averaged as one of three samples. As an example: if you have a printed circuit board that is 9" X 9" you need three of these boards and then cut each one into a 4.5"X 4.5" piece (sample1a and 1b). You would ship us a total of 6 pieces (a set of 3 for sample PCB-1a and a set of 3 for sample PCB-1b). *** For wires larger that 16 AWG and all multistrand cables the formula for quantity is 27/dia" = length in inches per mode. Example, cable diameter is 0.22" then 27/0.22=123" per mode (flaming / nonflaming) |

©copyright 2005